Introduction

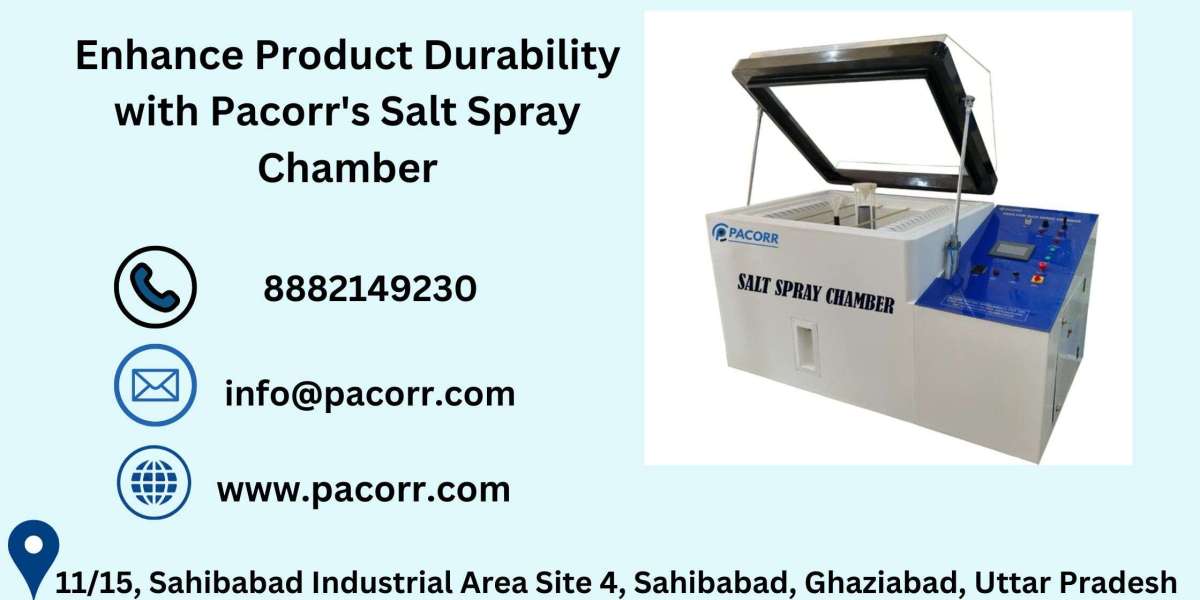

Corrosion is a persistent challenge faced by industries, impacting the durability and performance of metal products. Addressing this critical issue, Pacorr introduces its state-of-the-art Salt Spray Chamber, a reliable and advanced solution for corrosion resistance testing. Designed to meet international standards, the Salt Spray Chamber empowers manufacturers to evaluate product performance under extreme environmental conditions, ensuring high-quality and durable outputs.

What is a Salt Spray Chamber?

A Salt Spray Chamber is a specialized testing instrument used to simulate corrosive environments and evaluate the resistance of materials to corrosion. By exposing products to a saline mist or fog, the chamber replicates conditions such as marine environments, industrial pollution, and humidity to determine the durability of coatings, metals, and other materials.

Key Features of Pacorr’s Salt Spray Chamber

Advanced Technology

The chamber integrates cutting-edge technology to ensure precise control of temperature, humidity, and salt fog concentration.Compliance with Standards

It meets international standards like ASTM B117, ISO 9227, and JIS Z 2371, guaranteeing globally recognized testing processes.Durable Construction

Built with corrosion-resistant materials, Pacorr’s Salt Spray Chamber ensures longevity and consistent performance.User-Friendly Interface

The intuitive design and digital controls make it easy to operate, even for first-time users.Customizable Testing Parameters

Adaptable to various testing requirements, the chamber supports different test durations and salt concentrations.

Benefits of Using the Salt Spray Chamber

Ensures Product Durability

By identifying weak points in materials or coatings, manufacturers can improve product quality and extend lifespan.Reduces Financial Losses

Preventing corrosion-related failures minimizes replacement costs and enhances customer satisfaction.Meets Regulatory Standards

Testing with Pacorr’s chamber ensures compliance with industry regulations, boosting market competitiveness.Supports Diverse Applications

Ideal for automotive, aerospace, packaging, and construction industries, the chamber caters to a wide range of testing needs.

Applications of the Salt Spray Chamber

- Metal Coating Testing: Evaluating the effectiveness of anti-corrosion coatings on steel, aluminum, and other metals.

- Automotive Parts: Assessing corrosion resistance of components like fasteners, panels, and fixtures.

- Marine Equipment: Ensuring durability of products exposed to saline environments.

- Industrial Goods: Testing machinery parts, tools, and other industrial equipment.

Why Choose Pacorr’s Salt Spray Chamber?

Pacorr’s Salt Spray Test Chamber is engineered to deliver unmatched accuracy and reliability, backed by exceptional customer support and technical expertise. With its robust build and adherence to global standards, it has become the preferred choice for industries worldwide.

Conclusion

The Salt Spray Chamber Price by Pacorr is an indispensable tool for industries looking to ensure the durability and quality of their products. With its advanced features, precision testing capabilities, and compliance with international standards, the chamber sets a benchmark in corrosion resistance testing. To explore more about the Salt Spray Chamber, visit pacorr.com.

Frequently Asked Questions (FAQs) about Salt Spray Chamber

Q1: What is the purpose of a Salt Spray Chamber?

A: A Salt Spray Chamber simulates corrosive environments to test the resistance of materials and coatings to corrosion. It helps manufacturers ensure product durability and compliance with quality standards.

Q2: Which industries benefit from using a Salt Spray Chamber?

A: Industries like automotive, aerospace, marine, construction, and manufacturing extensively use Salt Spray Chambers to evaluate corrosion resistance in their products.

Q3: How does Pacorr’s Salt Spray Chamber comply with international standards?

A: Pacorr’s chamber meets standards such as ASTM B117, ISO 9227, and JIS Z 2371, ensuring globally accepted testing protocols.

Q4: Can the Salt Spray Chamber test non-metal materials?

A: Yes, the chamber can test non-metal materials like coatings, polymers, and paints for their resistance to corrosive environments.

Q5: How long does a typical salt spray test take?

A: The duration depends on the material and the standard being followed. Tests can range from a few hours to several days.

Q6: What types of corrosion can be evaluated using the Salt Spray Chamber?

A: It evaluates general corrosion, pitting corrosion, and the effectiveness of anti-corrosion coatings.

Q7: Is the Salt Spray Chamber difficult to operate?

A: Pacorr’s Salt Spray Chamber features a user-friendly interface with digital controls, making it easy to operate for both experienced and new users.

Q8: What maintenance does a Salt Spray Chamber require?

A: Regular cleaning, inspection of nozzles, and checking of salt solution levels are necessary for optimal performance.

Q9: Can I customize the test parameters in Pacorr’s Salt Spray Chamber?

A: Yes, the chamber allows customization of temperature, humidity, and salt fog concentration to suit specific testing needs.

Q10: What is the lifespan of Pacorr’s Salt Spray Chamber?

A: Built with durable, corrosion-resistant materials, the chamber is designed for long-term use with minimal maintenance.